We use cookies to make your experience better. To comply with the privacy directives, we need to ask for your consent to set the cookies. Learn more.

Beginnings of Arc'teryx

Named after the first animal to develop the flight feather, Arc'teryx too has been pushing back the limitations placed upon us by the extremes of climate and weather, especially at altitude. Their logo adorns the chests of extreme Alpine athletes and wildlife cameramen alike, and they are regarded as one of the most technical and highest quality producers of outdoor wear there are.

Originally named Rock Solid, Arc'teryx is based in Vancouver on the East coast of Canada which is the perfect testing ground for their products. Arc'teryx came to be through the development of the very first climbing harness to use moulded, multi-dimensional foam in its' design. Previously climbing harnesses were made flat and did not take in to consideration how they fit the human form. By way of a mould and rapid heating/cooling they achieved the result of 'Thermoformed 3D', a design that is now incorporated into their backpacks as well as their climbing harnesses. When they started production of their active wear in 1998, they carried forward their innovative approach and strived to create the lightest and best performing apparel possible.

Quality First

Each of Arc'teryx's garments are pain stakingly hand made, most of which, in Vancouver. As an example an Alpha SV jacket will take 4 hours 38 minutes to make and will come in to contact with 65 different operators. All garments go through a rigorous inspection program, with a third of all products being randomly tested for quality and waterproofness. Even before the commencement of a garment, a third of all the raw materials used are inspected for flaws and inconsistencies. It is this attention to detail and quality that ensures Arc'teryx products will not fail, even when tested to the limits by the elements.

The production of a single Alpha SV Jacket at the Manor Street factory, Vancouver:

- Number of operations: 211

- Number of minutes spent cutting: 24.149

- Number of minutes spent sewing: 222.157

- Number of minutes spent finishing: 32.376

- Total number of operators who touch the jacket: 65

Unmatched Lamination

Arc'teryx's research and development of lamination processes between materials is unparalleled. They use laminated processes within the production of their outerwear and hard goods and permanently bond the layers of material by use of heat, pressure or adhesives. The benefit of this lamination technology is that the end product benefits from being much lighter and more durable than counterparts that use seams to join layers together. So where weight and durability is a key factor, laminated garments are the only choice.

Fabrics

Arc'teryx's mission to use the lightest and most durable fabrics in its' products has led to partnerships with two of the worlds leading outdoor wear textile manufacturers. The leader in waterproof textiles is undoubtedly Gore-Tex, the two companies have worked together on researching and developing new, progressive fabrics that perform whilst withstanding the beating Arc'teryx's mountain athletes put them through. N80p-X, used in the Theta AR Gore-Tex Ski Jacket, is just one result of their collaborative efforts. It was developed when their athletes required a face fabric that possessed a tougher, more abrasion resistant surface that remained waterproofed.

Another progressive partnership was formed with Polartec, a company formed from Walden Mills, that produced the first synthetic fleece in 1981. The synthetic fleece still remains the primary choice of insulation for use in colder environments. This meeting of minds saw the development of the Gamma series of softshells. Through lamination processes and fusion of a stretchy woven exterior fabrics and wicking interior fabrics they created a softshell layer that is both wind resistant and highly breathable whilst offering great mobility.

Ergonomics

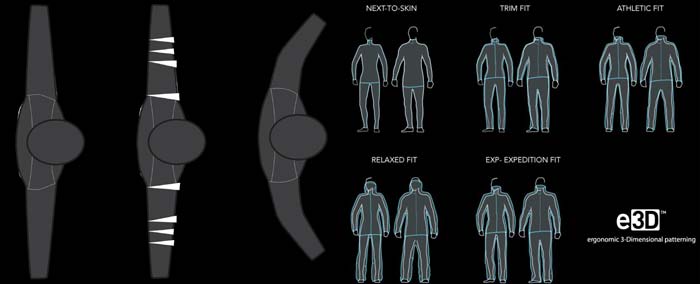

Another element of Arc'teryx garments is their attention to the ergonomics of their apparel. Not just how the item looks when stationary but how it reacts when at full use. Their jackets for example feature arms that are positioned further forward to prevent sleeves riding up too far or pull the jacket tight against your back when lifting your arms. Their trousers do not pull tight on your thigh or lift excessively when raising your leg. This results in a full freedom of movement when wearing Arc'teryx gear that provides a great feeling of liberty and comfort.

Lithic Comp Jacket

The development of the Lithic Comp jacket heralds the arrival of the next generation of composite technology from Arc'teryx. Working closely with long time associate W.L. Gore, they have created a backcountry touring jacket that features Gore-Tex waterproof fabrics in the areas you need them most; the hood, shoulders and front. While their own Trusaro softshell fabric is used on the back and under the arms providing stretch and breathability. This mapping of fabrics allows the perfect balance of heating and cooling that is part of any outdoor activities work and rest cycle. This results in an all day comfort thanks to fantastic body temperature regulation.